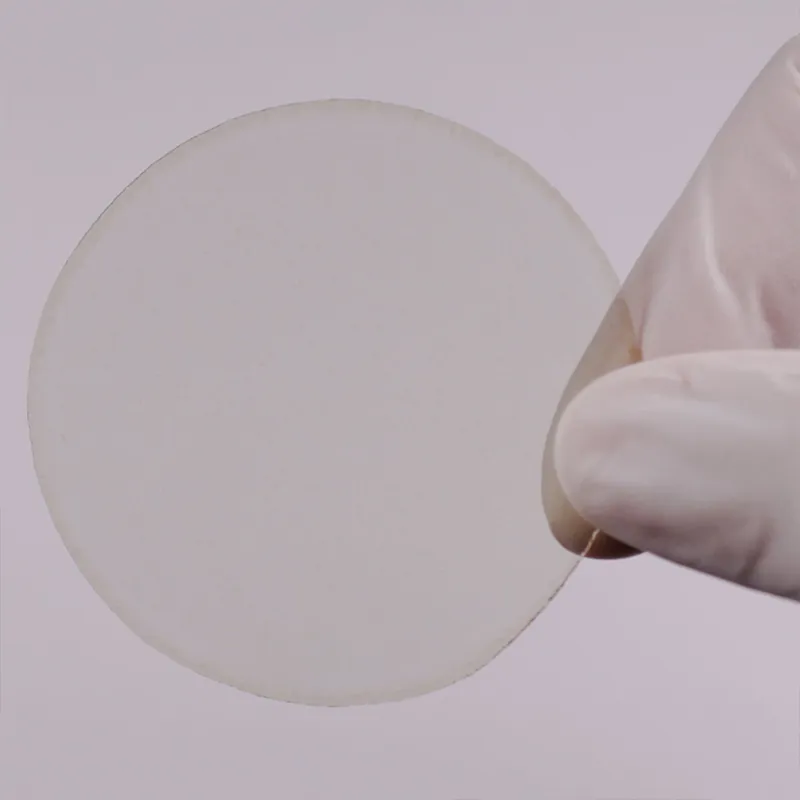

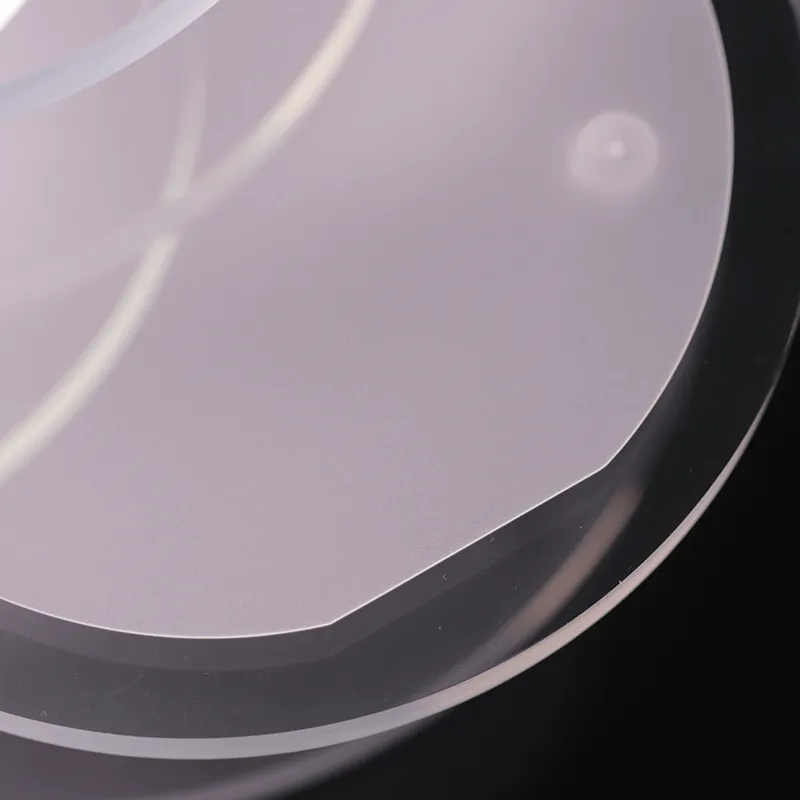

窒化アルミニウム(AlN)

窒化アルミニウム(AlN)単結晶基板は、高い熱伝導率、優れた電気絶縁性、低誘電損失、耐熱性を備えた次世代の電子材料です。特に、パワーエレクトロニクス、高周波デバイス、UV-LED、深紫外(DUV)光源、半導体パッケージなどの用途に適しています。

窒化アルミニウム(AlN)単結晶の製品をご提供しております。

ご希望の仕様についても対応可能ですので、お気軽にお問い合わせください。

窒化アルミニウム(AlN)単結晶基板

| Diameter (mm) | 10-50.8 mm or 10 × 10 mm or 10-20 mm or 5 mm-50.8 mm | ||

|---|---|---|---|

| Thickness (µm) | 400 ± 50 | ||

| Crystal Type | 2H | ||

| Orientation | {0001} ± 0.5° | ||

| Surface Finish | Al face: CMP (double side polishing is customizable) | ||

| Roughness | Al face: ≤0.5 nm N face (backside): ≤1.2 μm |

||

| Shape | Round / Rectangle / Quadrangle | ||

| Grade | S (Super) | P (Production) | R (Research) |

| FWHM-HRXRD@(0002) (arcsec) | ≤150 | ≤300 | ≤500 |

| FWHM-HRXRD@(10-12) (arcsec) | ≤100 | ≤200 | ≤400 |

| Absorption Coefficient@265nm (cm-1) | ≤50 | ≤70 | ≤100 |

| Edge Exclusion (mm) | 1 | 1 | 1 |

| Scratches | None | None | None |

| Edge Chips | None | None | ≤3total cumulative length≤1.0 mm |

| Usable Area | ≥90% | ||

| Primary Flat Orientation | {10-10} ± 5.0° | ||

| Secondary Flat Orientation | 90°±5 CW from Primary Flat, as viewed from Al face 90°±5 CCW from Primary Flat, as viewed from N face |

||

| TTV (µm) | ≤30 | ||

| Bow (µm) | ≤30 | ||

| Wrap (µm) | ≤30 | ||

| Cracks | None, by naked eye, high intensity light | ||

| Surface Contamination | None, by naked eye, diffuse light | ||

| Laser Marking | N face, parallel to primary flat | ||

| Packaging | Single wafer cups | ||

| Element | C | O | Si | B | Na | W | P | S | Ti | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| PPMW | 81 | 110 | 9.7 | 0.92 | 0.23 | <0.1 | <0.1 | <0.5 | 0.46 | <0.5 |

| Properties | Reference |

|---|---|

| Crystal Structure | Wurtzite |

| Lattice Constant (Å) | a=3.112, c=4.982 |

| Conduction Band Type | Direct Bandgap |

| Density (g/cm3) | 3.23 |

| Surface Microhardness (Knoop test) | 800 |

| Melting Point (℃) | 2750 (10-100 bar in N2) |

| Thermal Conductivity (W/m·K) | 320 |

| Band Gap Energy (eV) | 6.28 |

| Electron Mobility (V·s/cm2) | 1100 |

| Electric Breakdown Field (MV/cm) | 11.7 |

| Acoustic Wave Velocity (m/s) | 11300 |

Sapphire on AlScNテンプレート

| Diameter (inch) | 2 | 4 | 6 |

|---|---|---|---|

| Substrate | C-plane of sapphire | ||

| Substrate Thickness (µm) | 430 ± 15 | 650 ± 20 | 1300 ± 20 |

| Sc Concentration (at%) | 40 ± 5 | ||

| AlScN Film thickness (nm) | 800 | ||

| Orientation | C-axis [0001] +/- 0.2° | ||

| Usable Area | ≥95% | ||

| Cracks | None | ||

| FWHM-HRXRD@(0002) (arcsec) | ≤120 | ||

| Surface Roughness@[5 × 5µm] (nm) | ≤10 | ||

| TTV (µm) | ≤10 | ≤20 | ≤20 |

| Bow (µm) | ≤20 | ≤40 | ≤60 |

| Warp (µm) | ≤20 | ≤40 | ≤60 |

| Packaging | Single/Multi Wafer Cups | ||

Si on AlScNテンプレート

| Diameter (inch) | 4 | 6 | 8 |

|---|---|---|---|

| Substrate | C-plane of Si single crystal wafer | ||

| Substrate Thickness (µm) | 525 ± 20 | 625 ± 15 | 725 ± 15 |

| Sc Concentration(at%) | 40 ± 5 | ||

| Conductivity Type | N/P | ||

| AlScN Film thickness (nm) | 800 | ||

| Orientation | C-axis [0001] +/- 0.2° | ||

| Usable Area | ≥95% | ||

| Cracks | None | ||

| FWHM-HRXRD@(0002) (arcsec) | ≤2° | ||

| Surface Roughness@[5 × 5µm] (nm) | ≤5 | ||

| TTV (µm) | ≤10 | ≤5 | ≤40 |

| Bow (µm) | ≤25 | ≤40 | ≤40 |

| Warp (µm) | ≤25 | ≤40 | ≤40 |

| Packaging | Single/Multi Wafer Cups | ||

Sapphire on AlNテンプレート

| Substrate | C-plane of sapphire | ||

|---|---|---|---|

| AlN Structure | Wurtzite | ||

| Diameter (inch) | 2 | 4 | 6 |

| Substrate Thickness (µm) | 430 ± 15 | 650 ± 20 | 1300 ± 20 |

| AlN Film thickness (nm) | 200/400/600/800/1000 (Technical specs may vary with AlN film thickness, hereby taking 200nm as an example) |

||

| Orientation | C-axis [0001] +/- 0.2° | ||

| Usable Area | ≥95% | ||

| Cracks | None | ||

| Back Surface Finish (µm) | RMS<1.2 | ||

| FWHM-HRXRD@(0002) (arcsec) | <100 | ||

| FWHM-HRXRD@(10-12) (arcsec) | <350 | ||

| Surface Roughness@[5 × 5µm] (nm) | Ra≤2 | ||

| TTV (µm) | ≤10 | ≤20 | ≤20 |

| Bow (µm) | ≤20 | ≤40 | ≤60 |

| Warp (µm) | ≤20 | ≤40 | ≤60 |

| Packaging | Single/Multi Wafer Cups | ||

Si on AlNテンプレート

| Substrate | C-plane of Si single crystal wafer | ||

|---|---|---|---|

| Conductivity Type | N/P | ||

| Resistivity (Ω) | >5000 | ||

| AlN Structure | Wurtzite | ||

| Diameter (inch) | 4 | 6 | 8 |

| Substrate Thickness (µm) | 525 ± 20 | 625 ± 15 | 725 ± 15 |

| AlN Film Thickness (nm) | 200/400/600/800/1000 (Technical specs may vary with AlN film thickness, hereby taking 500nm as an example) |

||

| Orientation | C-axis [0001] +/- 0.2° | ||

| Usable Area | ≥95% | ||

| Cracks | None | ||

| FWHM-2θXRD@ (0002) | ≤0.2° | ||

| FWHM-HRXRD@ (0002) | ≤1.55° | ||

| Surface Roughness [5 × 5µm] (nm) | ≤2.0 | ||

| TTV (µm) | ≤10 | ≤5 | ≤4 |

| Bow (µm) | ≤25 | ≤40 | ≤40 |

| Warp (µm) | ≤25 | ≤40 | ≤40 |

| Packaging | Single/Multi Wafer Cups | ||