Silicon Wafers

We provide silicon wafers used as semiconductor substrates ranging from 2 inches to 12 inches, depending on customer's application and requests.

We have wide selection of products from major manufacturers, and we can propose wafers that are optimal for applications and plans of various manufacturers, universities, and research institutes.

We stably supply wafers of reliable quality that meet customer requests.

| Item | Unit | Specifications | ||||||

|---|---|---|---|---|---|---|---|---|

| Size | Inch | 2 | 3 | 4 | 5 | 6 | 8 | 12 |

| Thickness | μm | 280 ± 25 | 380 ± 25 | 525 ± 25 | 625 ± 25 | 625 ± 25 | 725 ± 25 | 775 ± 25 |

| Manufacture | - | CZ/FZ | ||||||

| Crystal Orientation | - | <100>/<111>/No Preference | ||||||

| Type | - | P/N/No Preference | ||||||

| Resistivity | Ω·cm | 0.01-1,000 | ||||||

| Surface Finish | - | Double-sided/Single-sided Mirror | ||||||

| Back Surface Finish | - | Double-sided/Single-sided Mirror | ||||||

| Packing Form | - | Coin Roll/Cassette Case | ||||||

Silicon Ingot

Product Description

- Using manufacturing method called the CZ method (Czochralski method), we manufacture single crystal ingots, which are material for silicon wafers.

- This ingot is very important consumable material used primarily in etching process, which is one of device manufacturing processes.

- We can provide silicon ingot products in various sizes and resistivities according to customer requirements.

| Diameter (mm) | Type | Crystal Orientation | Purity | Resistance Value (Ω·cm) | Length |

|---|---|---|---|---|---|

| φ200-φ550 | P | <100>/<111> | 10-11 N | ≤0.01 | Custom-made |

| 1-4 | |||||

| 60-90 | |||||

| Custom-made |

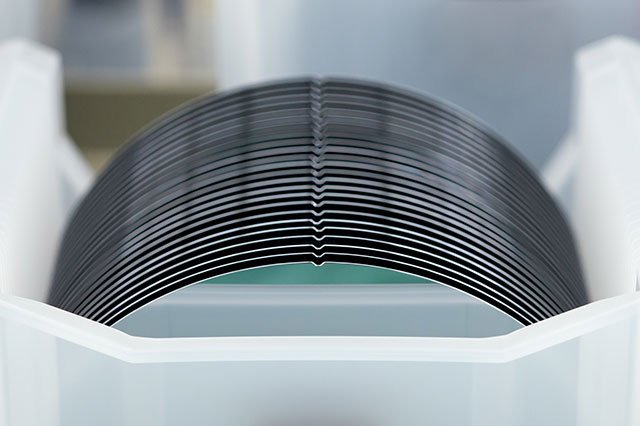

Dummy Wafer

Strengths

- Wide range of products

- We carry wide variety of silicon wafers.

- Small lots available

- We can respond to customer requests with care and detail.

- Short delivery times

- We utilize our abundant inventory to provide products in short delivery times.

- Flexible response

- We can also process from ingots for standards that cannot be covered with stock wafers

We can process ingots even for specifications that are not in stock.

Through careful interviews with our customers, we propose optimal wafer that meets their needs. We can also ship in a format according to your request, such as in cassette case or coin roll case. Furthermore, we can sell wafers of any type or thickness at low cost.

Features

Because they are often used in experiments and tests, dummy wafers come in wide variety of sizes and thicknesses. In some cases, reclaimed wafers may also be used.

Compared to particle-controlled silicon wafer products, dummy wafers are cheaper and can be shipped in small lots. This is major feature of dummy wafers.

In manufacturing equipment, dummy wafers are sometimes used for first few wafers to improve process stability. It is also used to optimize and monitor manufacturing processes. Although dummy wafers are not suitable for device manufacturing, they exhibit sufficient performance for monitoring and testing purposes, and are widely used as replacement for new wafers.

Dummy wafers are indispensable and play important role in testing and adjustment in each process of wafer manufacturing.

| Item | Specification | ||||||

|---|---|---|---|---|---|---|---|

| Size | 2 | 3 | 4 | 5 | 6 | 8 | 12 |

| Production Method | CZ/FZ | ||||||

| Type | P-type/N-type/No Preference | ||||||

| Crystal Orientation | <100>/<111>/<110>/No Preference | ||||||

| Notch/Off Orientation | <100>/<111>/<211>/No Preference | ||||||

| Thickness (μm) | 280 | 380 | 525 | 625 | 625/675 | 725 | 775 |

| Thickness Tolerance (μm) | 20 | 20 | 25 | 25 | 25 | 25 | 25 |

| Resistivity (Ω·cm) | 0.005~/No Preference | ||||||

| Olyfla | Olyfla | Olyfla | Olyfla | Olyfla | Notch/Olyfla | Notch/Olyfla | Notch |

| Surface Finish | One-Sided Mirror (MP/ET)/Both Sides Etched (ET/ET) | Both Sides Mirror (MP/MP) | |||||

| Particle | No Preference | ||||||

| Quantity | Orders are accepted from 25 pieces. | ||||||

| Packaging Type | Coin Roll/Cassette Case | ||||||

| Remarks | The 6-inch OriFla standard can be adapted to both JEITA and SEMI. | ||||||

Recycled Wafer

We utilize cutting-edge equipment along with high-standard chemical processing, polishing, and cleaning technologies to provide high-quality recycled wafers ranging from 8-inch to 12-inch sizes.

Recycled wafers refer to wafers that have been used as dummy/test wafers for equipment calibration and testing purposes in semiconductor manufacturing processes. These wafers are cleaned to remove contaminants, re-polished, and re-cleaned, making them reusable for repeated applications.