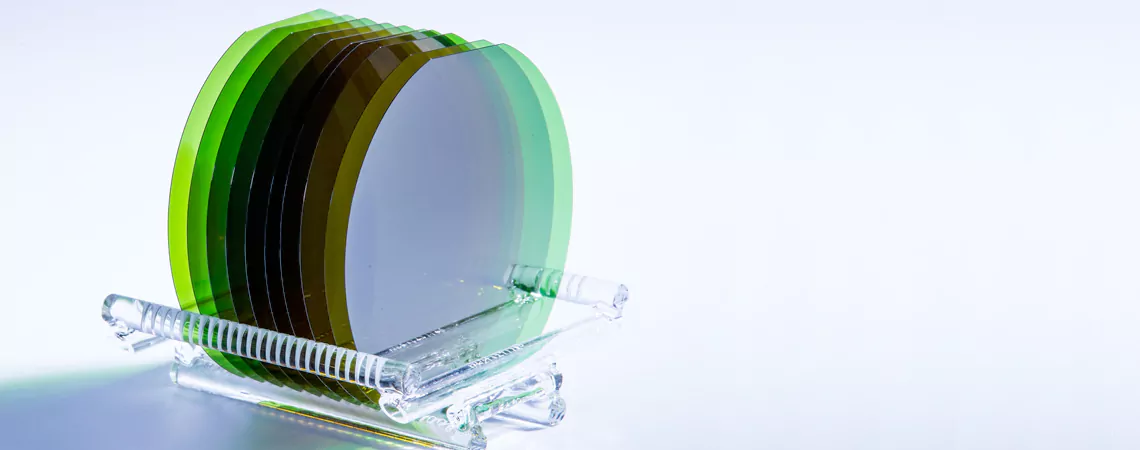

SiC Wafer

We provide single crystal SiC products.

- 2-4 inch 4H/6H-P SiC Wafer

- 2-4 inch 3C SiC Wafer

- 4-6inch 4H-Semi-insulating SiC Wafer

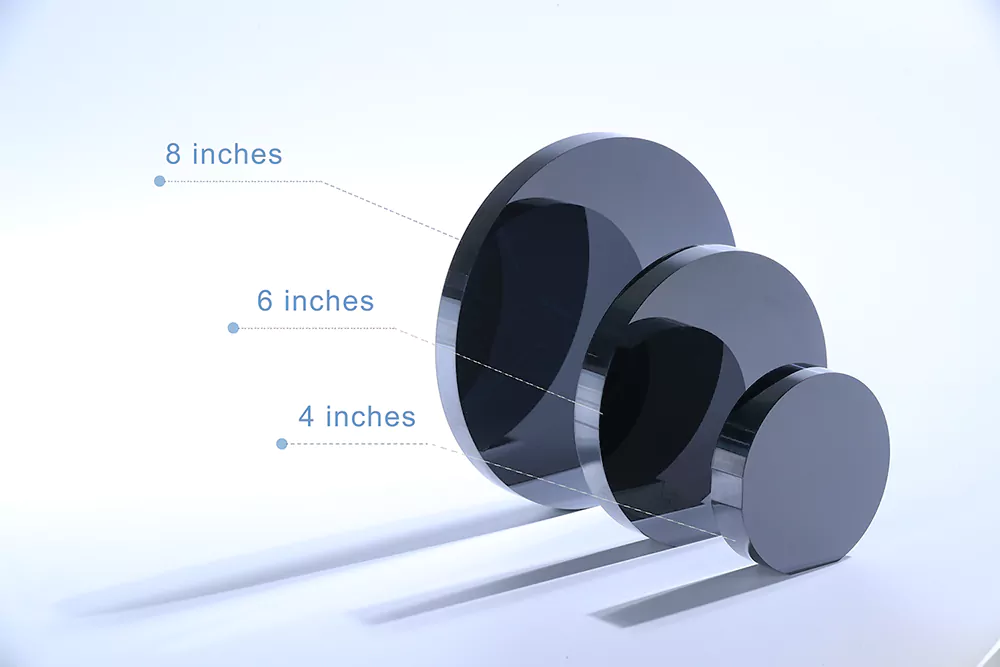

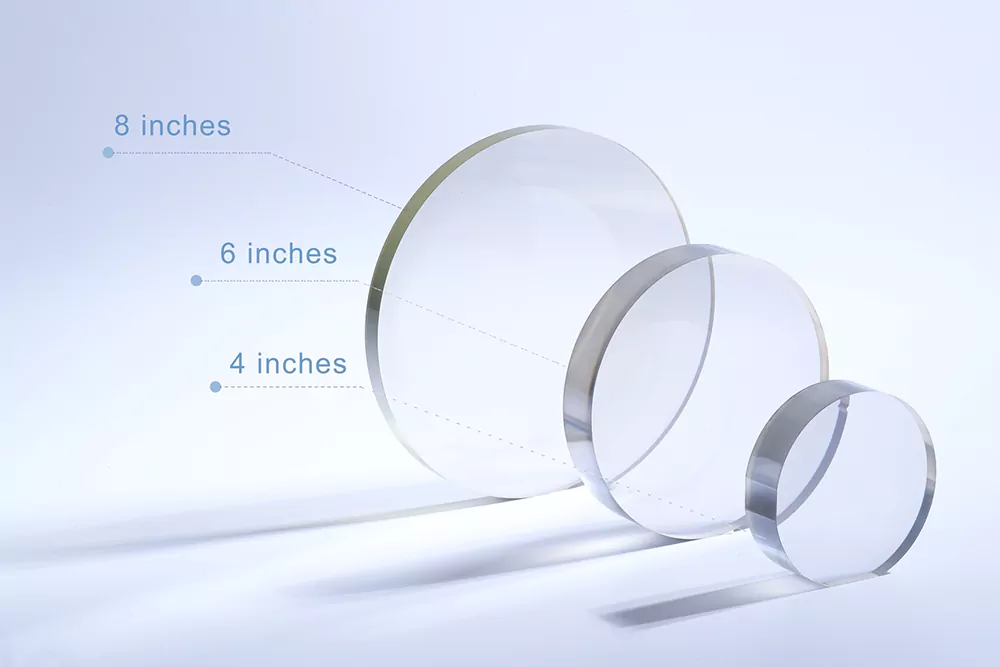

- 4-8 inch 4H-N SiC Wafer

- 4-8 inch SiC Ingot

- 4-8 inch SiC Epitaxial Wafer

SiC wafers are expected to see increased use in power devices in the future.

In addition to 2, 4, 6, and 8 inches, we also handle substrates from 5 mm square to 10 mm square.

SiC Wafer

| Size | Type | Off-Angle | Grade | Number of Micropipes | Thickness | Surface Finishing |

|---|---|---|---|---|---|---|

| 5 mm × 5 mm | 4H-P | 2.0° – 4.0° ± 0.5° | Dummy | <0.1 cm-2 | 350 ± 25 μm | Si Surface: CMP Finishing C Surface: Optical Mirror Finishing (Mirror) |

| 6H-P | ||||||

| 3C-N | <0001> ± 0.5° | |||||

| 10 mm × 10 mm | 4H-P | 0°~4° ± 0.5° | ||||

| 6H-P | ||||||

| 3C-N | <0001> ± 0.5° | |||||

| 2 inch | 4H-N | 4° ± 0.5° | Dummy | - | 350 ± 25 μm 1000 ± 25 μm ※ |

|

| 4H Semi-Insulating | <0001> ± 0.2° | Dummy | - | 500 ± 25 μm (DSP) 350 ± 25 μm (SSP) ※ |

||

| 4H-P | 0°~4° ± 0.5° | Dummy | <0.1 cm-2 | 350 ± 25 μm | ||

| 6H-P | ||||||

| 3C-N | <0001> ± 0.5° | |||||

| 4 inch | 4H-N | 4° ± 0.5° | Prime | - | 350 ± 25 μm 800 ± 25 μm ※ |

|

| Dummy | - | |||||

| 4H Semi-Insulating | 0° ± 0.2° | Prime | - | 500 ± 25 μm (DSP) 350 ± 25 μm (SSP) ※ |

||

| Dummy | - | |||||

| 4H-P | 0°~4° ± 0.5° | Dummy | ≤10 cm-2 | 350 ± 25 μm | ||

| 6H-P | <0.1 cm-2 | |||||

| 3C-N | <0001> ± 0.5° | |||||

| 6 inch | 4H-N | 4° ± 0.5° | Prime | ≤0.1 cm-2 | 350 ± 25 μm | |

| Production | ≤1 cm-2 | |||||

| Dummy | ≤5 cm-2 | |||||

| 4H Semi-Insulating | 0° ± 0.2° | Prime | ≤0.5 cm-2 | 500 ± 25 μm | ||

| Production | ≤2 cm-2 | |||||

| Dummy | ≤5 cm-2 | |||||

| 8 inch | 4H-N | 4° ± 0.5° | Prime | ≤0.1 cm-2 | 350 ± 25 μm 500 ± 25 μm |

|

| Production | ≤0.1 cm-2 | |||||

| Dummy | ≤5 cm-2 | |||||

| 4H Semi-Insulating | 0° ± 0.2° | Prime | ≤0.5 cm-2 | 500 ± 25 μm | ||

| Production | ≤2 cm-2 | |||||

| Dummy | ≤5 cm-2 |

SiC Ingot

SiC Ingot

| Type | Off Angle | Grade | Number of Micropipes | Thickness | Surface Finishing | |

|---|---|---|---|---|---|---|

| SiC Ingot | 4 Inches 4H-N | 4° ± 0.5° | Dummy | ≤50 cm-2 |

|

Peripheral circular processing available Primary and secondary orifices available  |

| 6 Inches 4H-N | ||||||

| 8 Inches 4H-N |

SiC Epitaxial Wafer

| Size | 6 Inch | |

| Conductivity | N-type | |

| Dopant | Nitroger | |

| Doping Calculation Method | No-NA | |

| Concentration | Range | 9E14-1E19/cm3 |

| Tolerance | ±12% | |

| Uniformity | 0.06 | |

| Thickness | Range | 0.2–50 μm |

| Tolerance | ±8% | |

| Uniformity | 0.04 | |

| Defect | Die yield | ≥95% |

| Scratches | cumulative scratch length ≤150 mm | |

| Edge chips | ≤0.5 mm | |

| Backside cleanliness | 100% clean | |

| Surface Roughness (20 × 20 μm) | ≤0.5 nm | |