Metal-Based Composite Materials

- MMC(Ai/SiC composite material)

- We provide metal composite materials such as Metal Matrix Composites (Al/SiC) and spacers, substrates, housings, etc., mainly composed of Cu-Mo.

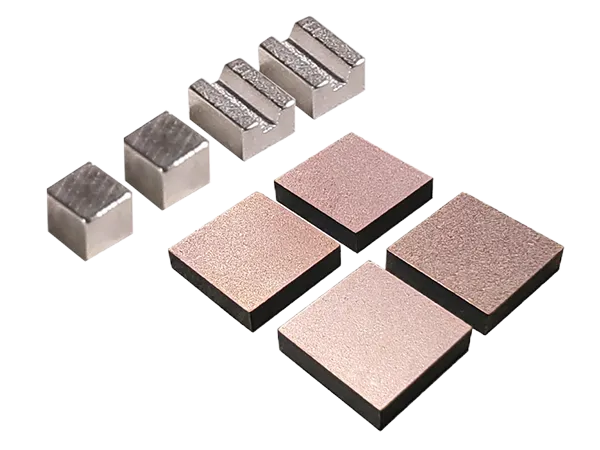

Spacer

- Introduction

- Double-sided cooling technology is a new structural technology for recent power module products. It effectively reduces the parasitic inductance and parasitic resistance of the device, thereby effectively improving the power density and reliability of the device.

This product serves as an essential primary material for devices such as double-sided cooling devices, mainly playing the roles of 'heat conduction', 'electrical conduction', and 'support'.

- Application Field

- Spacer-related products are applied in fields such as new energy vehicles, power electronics, and smart grids.

- Characteristics

-

- High thermal conductivity

- Low expansion

- High electrical conductivity

- Strong coupling

- Good weldability

| Materials | AlSiC | MoCu |

|---|---|---|

| Volume Fraction (Vol%) | 55~65 | 40±2 |

| Thermal Conductivity (W/m・K) | 200±20 | 300±20 |

| Thermal Expansion Coefficient (×10-6/K) | 9~11 | 10~13 |

| Electrical Conductivity (mS/m) | > 6 | > 40 |

| Density (g/cm3) | 2.93±0.03 | 9.42±0.03 |

| Titanium Plating (μm) | < 0.5 | / |

| Nickel Plating (μm) | 8~12 | 3~7 |

| Copper Plating (μm) | 20~30 | / |

| Silver Plating (μm) | 4~8 | 4~8 |

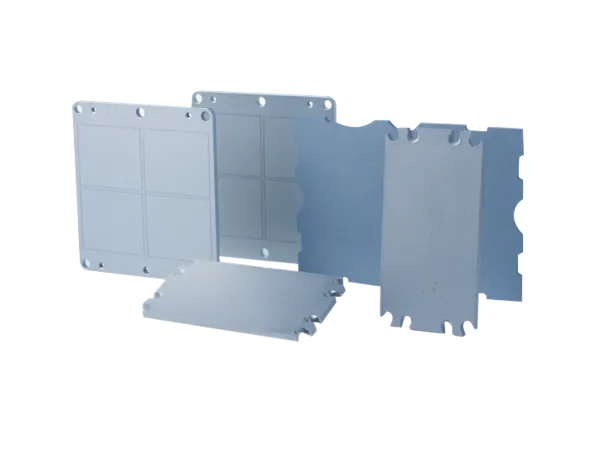

Baseplate

- Introduction

- AlSiC substrates are widely used in equipment equipped with high-power IGBT modules due to their excellent thermodynamic and mechanical properties.

- Application Field

- Substrate-related products are applied in fields such as railways, smart grids, and power electronics.

- Characteristics

-

- High thermal conductivity

- Low expansion

- High rigidity

- Strong bonding

- Good weldability

| Materials | AlSiC |

|---|---|

| Volume Fraction (Vol%) | 65~70 |

| Thermal Conductivity (W/m・K) | 200±20 |

| Thermal Expansion Coefficient (×10-6/K) | 6.5~9 |

| Electrical Conductivity (mS/m) | > 6 |

| Density (g/cm3) | 2.97~3.1 |

| Copper Plating (μm) | 8~12 |

| Gold Plating (μm) | > 1.3 |

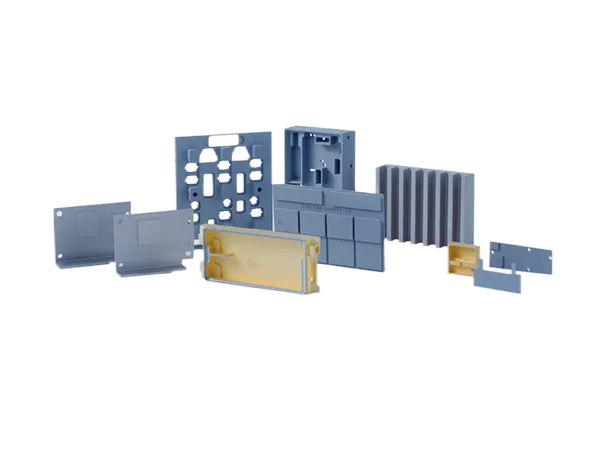

Housing

- Introduction

- In the machining industry, the development and evolution of diamond tools have made it possible to mechanically process AlSiC housings into various complex shapes. AlSiC housings are used as excellent packaging materials due to their superior thermodynamic and mechanical characteristics, light weight, and excellent airtightness, which are excellent for retaining heat.

- Application Field

- Housing-related products are applied in fields such as phased array radars, aerospace, and satellite communications.

- Characteristics

-

- High thermal conductivity

- Low expansion

- Low density

- High airtightness

- Strong coupling

- Strong coupling

- High dimensional stability

| Materials | AlSiC |

|---|---|

| SiC Content (Vol%) | 65 |

| Thermal Conductivity (W/m・K) | 200±20 |

| Thermal Expansion Coefficient (×10-6/K) | 6.5~9 |

| Bending Strength MPa | ≥300 |

| Density (g/cm3) | 2.93~3.1 |

| Airtightness Pa·m3/s | <10-9 |

| Nickel Plating (μm) | 8~12 |

| Gold Plating (μm) | >1.3 |

| Silver Plating (μm) | 4~8 |