Equipment Parts Processing Business

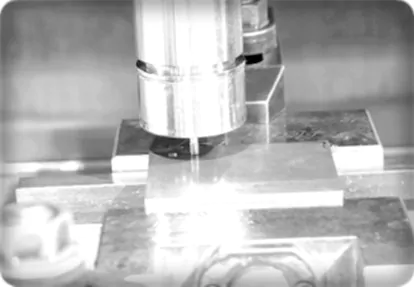

Equipment Introduction

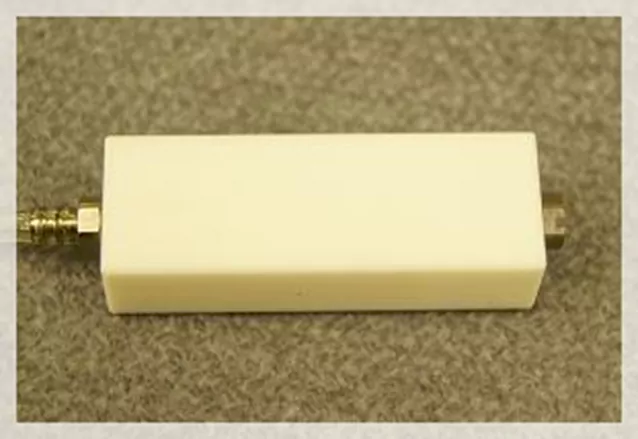

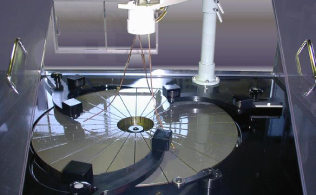

Gliding Center

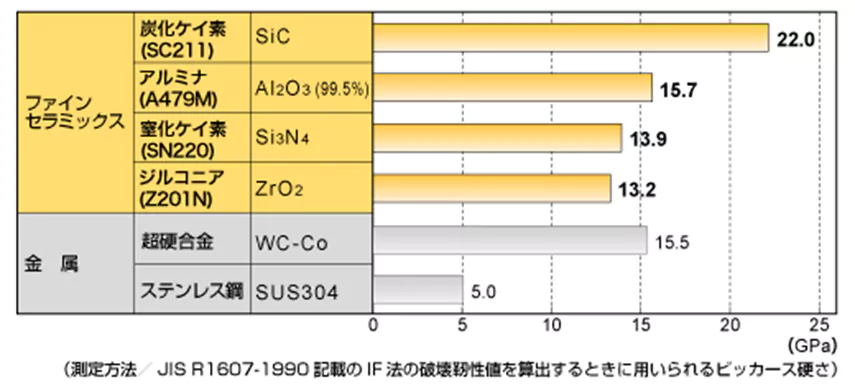

By taking advantage of these features, machining time can be significantly reduced compared to conventional machining. For example, with SiC, the feed rate is approximately twice as high.

Model GC-7 OKK Co., Ltd.

- Table Dimensions

- 1,550 × 740 mm

- Spindle Speed

- 12,000rom

- Taper No.50

-

X Movement Amount 1,530 mm

Y Movement Amount 740 mm

Z Movement Amount 660 mm

Laser automatic tool measurement function reduces machining time.

Equipped with a chip conveyor, filter, centrifuge, and mist separator to remove sludge and moisture.

Equipped with a 7 MPa high-pressure coolant unit that powerfully removes sludge adhering to tools and prevents clogging.

What can a gliding center do?

Cutting

We use drills, end mills, and blades to process flat surfaces, sides, grooves, and arcs. Mainly metal processing.

Grinding

Shape processing and final polishing of flat surfaces and sides are performed using diamond electrodeposition tools and grindstones. Ceramics, SiC, MMC, super steel alloys, etc.

Processing Example

Processing Classification

Grinding Material Classification Cemented Carbide

Tapping of Cemented Carbide

We can process taps from M3 to large diameter taps in a short time.We can process difficult-to-cut materials regardless of the type of carbide.

- Cemented Carbide

- High Hardness (HRA 80 to 94)

- High Strength (transverse rupture strength approximately 2 GPa) or higher

- Young's modulus is large (approximately 3 times that of iron)

- High specific gravity (approximately twice that of iron)

It is one of the materials that are difficult to process.

Select the tool as shown below depending on the required accuracy.

- Screw Accuracy

- JIS 1 Class

(General 2 Class)

<For General-Purpose Tapping>

<For Precision Tap Processing>

Processing Classification

Grinding Material Classification Alumina Ceramic

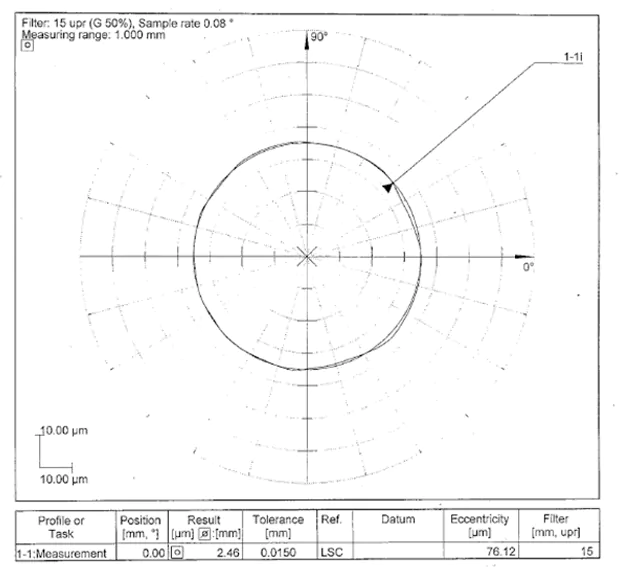

High-precision circular machining of ceramics

High precision circular processing

Roundness: 3 μm or less

Tools Used

Equipment Used

- Accuracy: Roundness

- 3μm or less

Processing Classification

Grinding Material Classification SiC

Machining of SiC Materials

We perform high-precision drilling, shape processing, and grinding on high-hardness SiC materials.

- Example) Reduction of processing time by 50%

- The feed rate has been improved from 150 to 300 mm/min (cutting in at 0.01 mm).

- SiC (Silicon Carbide)

- SiC (Silicon Carbide) is the hardest, most wear-resistant, and corrosion-resistant material among fine ceramics.

Processing Classification

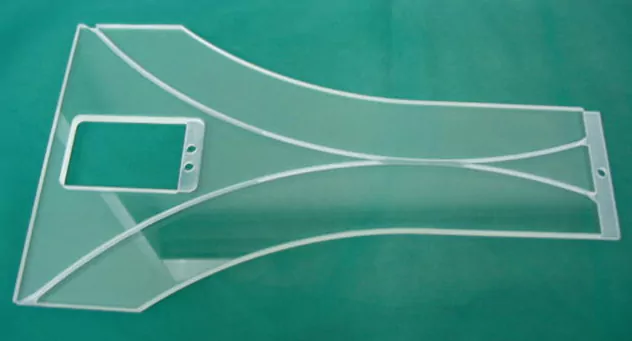

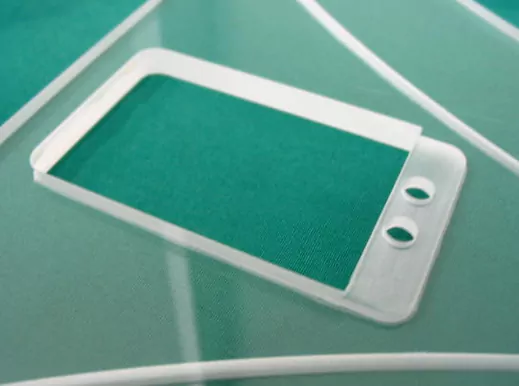

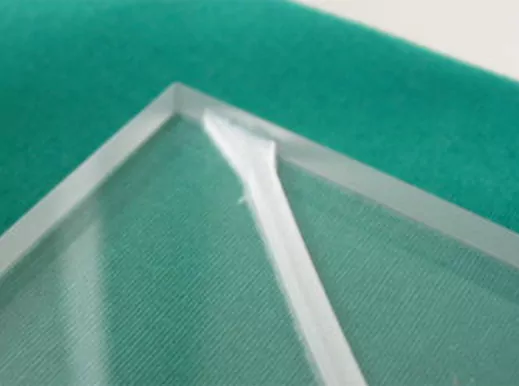

Grinding Material Classification Heat Resistant Tempered Glass

Processing of Heat-Resistant Tempered Glass

We perform precision drilling and shaping of heat-resistant tempered glass.

Example of High-Precision Shape Processing

Special Processing to Minimize Chipping

Tools Used

- Pitch/Diameter Accuracy

- Below 10 μm

Processing Classification

Grinding Material Classification Macall

Makor (Free-Cutting Ceramic) Processing

Makor (Free-Cutting Ceramic) is Processed With High Precision.

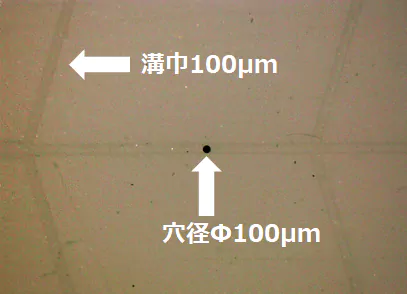

Capable of tapping and grooving from 100 μm

- ● What is Makor (Machinable Ceramics)

- A new ceramic material that shares the characteristics of glass and ceramics and the ease of metal processing. normal ceramics Impossible ultra-precision finishing or, Processed into complex shapes Is possible.

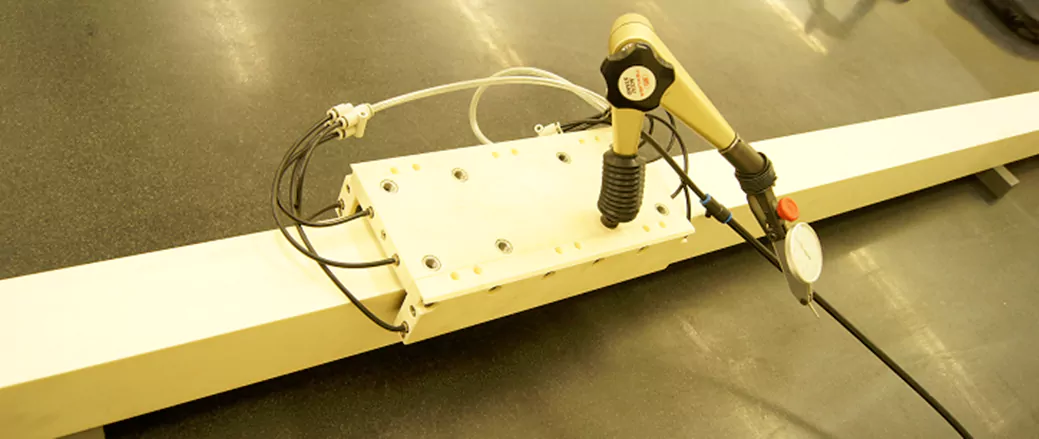

Example of product of groove type air pad

Processing Classification

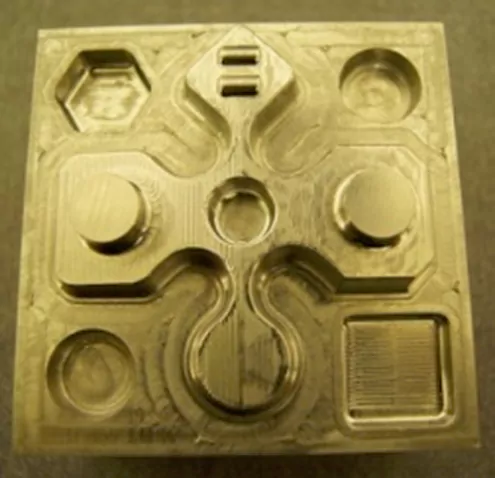

Grinding Material Classification Hardened Material

Shape processing after quenching

Hot die steel SKD61 ※Test data next page

Processing Example

Pre-heat treatment processing

Post-heat treatment finishing process

Tools Used

- Processing Accuracy

- (Target ± 10 μm)

Position 10 μm

Shape 10 μm

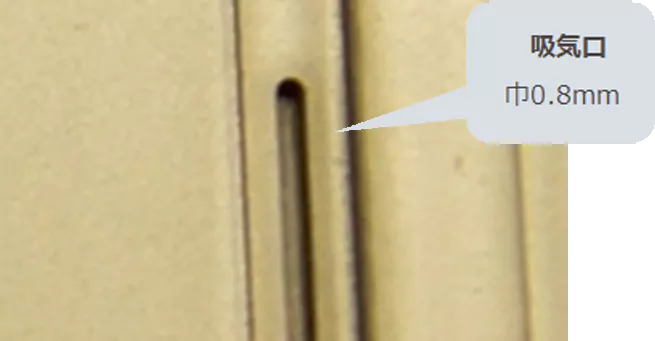

Make Categories Hand

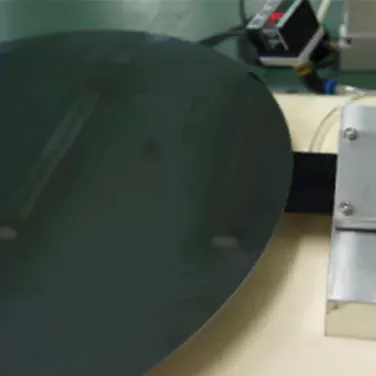

Hand Production for Semiconductor Wafers

- Various precise shape processing

- Surface accuracy construction of the suction surface

- Conductive fluorine coating

- Simple air leak test

- Precision cleaning compatible with clean specifications

Production Flow

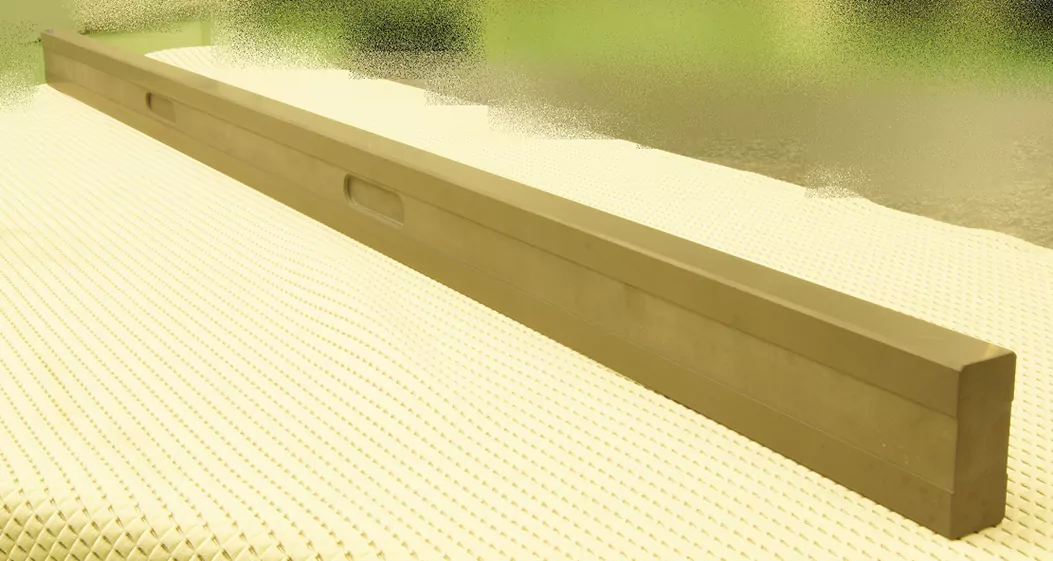

Make Categories Straightedge

Making a straightedge

- We will make it to your desired size.

- Straightness: 2 μm, flatness: 1 μm

Make Categories Square Ruler

Making a Right Angle Master

- We will make it to your desired size.

The photo is 500 mm square - Straightness: 2 μm, flatness: 1 μm

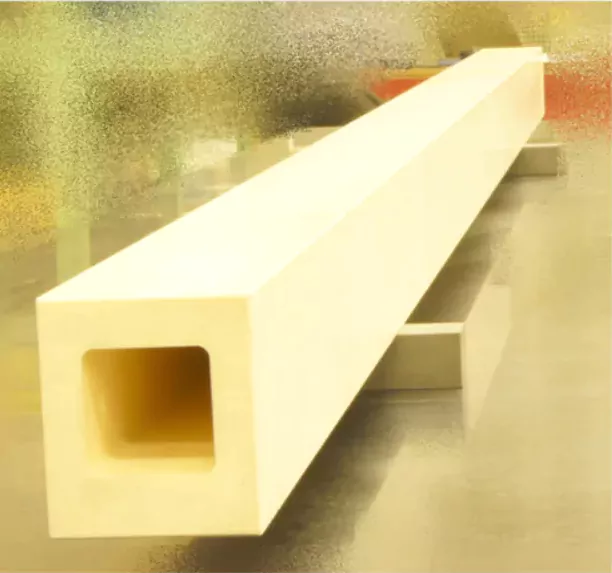

Make Categories Straightedge

Manufacture of a straight edge (square)

- We will custom make to your desired size.

Up to 80 × 80 × 3,200 mm - Straightness 2 μm, Flatness 1 μm

Production Example Using a Straight Edge Rule (L-Shaped)

Polishing of Wide Gap Semiconductor Materials

- Material

- SiC (Silicon Carbide), GaN (Gallium Nitride), Sapphire Wafers, etc.

- Specifications

-

2, 3, 4 and 6 inch wafers

- SBIR ≦ 1 μm

- GBIR ≦ 2 μm

- Ra ≤ 0.1 nm or less

- Quality

-

Quality assurance by the latest inspection equipment

- Candela

- NIDEK

- AFM

- TXRF

- Edge Profiler

- Features

-

High flatness and heavy metal-free cleaning

- Substrate polishing

- Epi-growth wafer backside polishing

- Patterned wafer polishing (edge trimming + backside polishing + heavy metal-free cleaning)

- Used wafer regeneration polishing

- Edge trimming and laser marking

Compound Semiconductor Wafer Polishing

- Material

- Substrate wafers such as GaP, GaAs, InP, epi-grown wafers, patterned wafers

- Specifications

-

2, 3, 4, 6-inch regular and irregular wafers

- Super thin finish possible (up to 50μm level)

- Substrate polishing has epi-ready surface quality

- Quality

-

Quality assurance by the latest inspection equipment

- Candela

- NIDEK

- AFM

- Features

-

- Ultra-thin finish

- Supports irregular wafers