Ultrasonic Green Working Machinery

By adopting Ultrasonic Green Technology in numerically controlled machine tools, we achieve efficient, environmentally-friendly high-end manufacturing and support the attainment of dual carbon goals!

Ultrasonic Green Working Machinery Series

TOYOKOU Ultrasonic Green Working Machinery

10 types, 32 series, and 188 specifications

Application Scene Advantages | 3+A

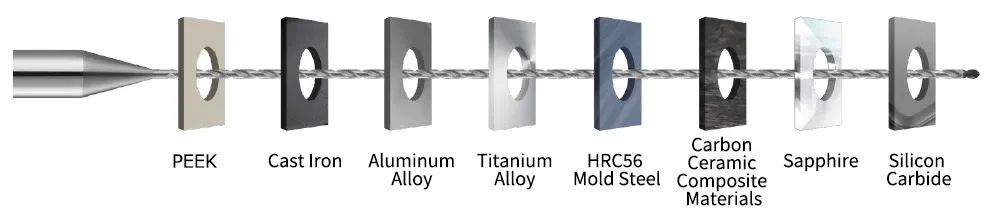

Hard Brittle Materials

Composite Materials

Difficult-to-cut Metal Materials

3

There are clear advantages in the processing characteristics of each of the three types of materials.Hole Machining (all types of materials)

A

There are clear advantages to hole machining, regardless of the material.Representative Machine Tools and Examples

Processed Products

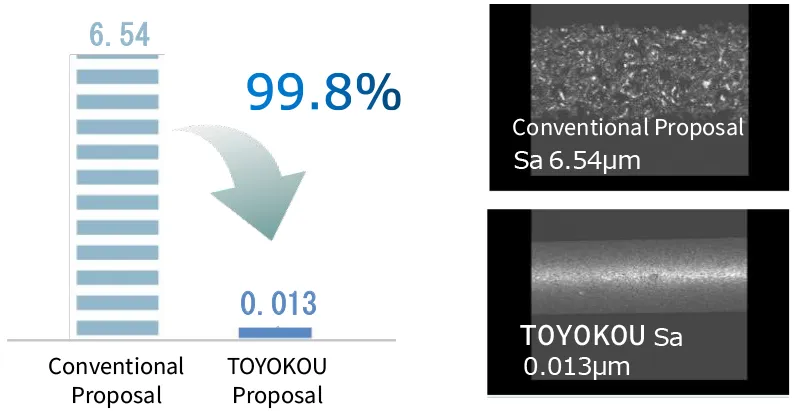

Monocrystalline Silicon Spray Disc

D0.45×24.75mm Blind Hole

Complete Solutions

- Ultrasonic Processing System

- Integrated PCD Micro Drill

Processing Advantages

- Drill Life >1000 holes

- Hole Roundness 0.003mm

- Hole Wall Roughness Sa Value <0.013μm

Data Comparison

Hole Wall Roughness Sa (μm)

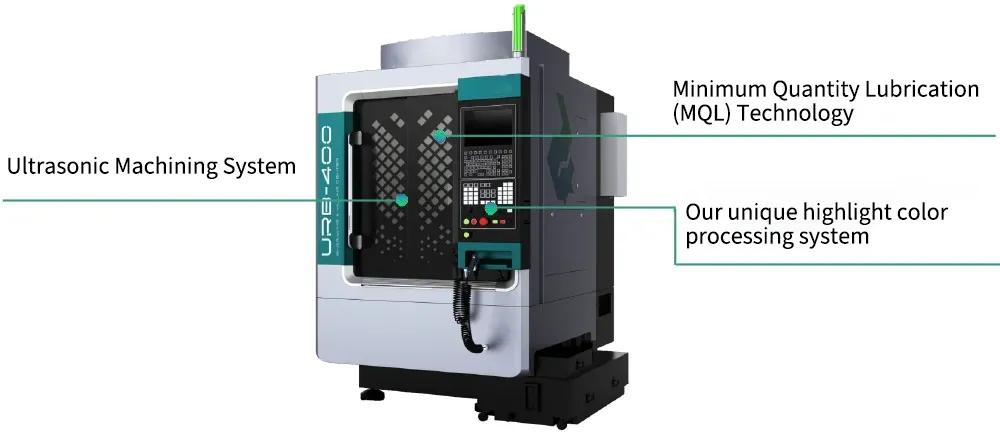

Ultrasonic Green Colorful Machining Center

Processed Products

Total Solutions

- Ultrasonic Machining System

- MCD Diamond Cutting Tools

- High Frequency Vibration Cutting

Processing Advantages

- The fine structure of the surface is regular, and the knife pattern is delicate

- Unique Highlight | Colorful Effect

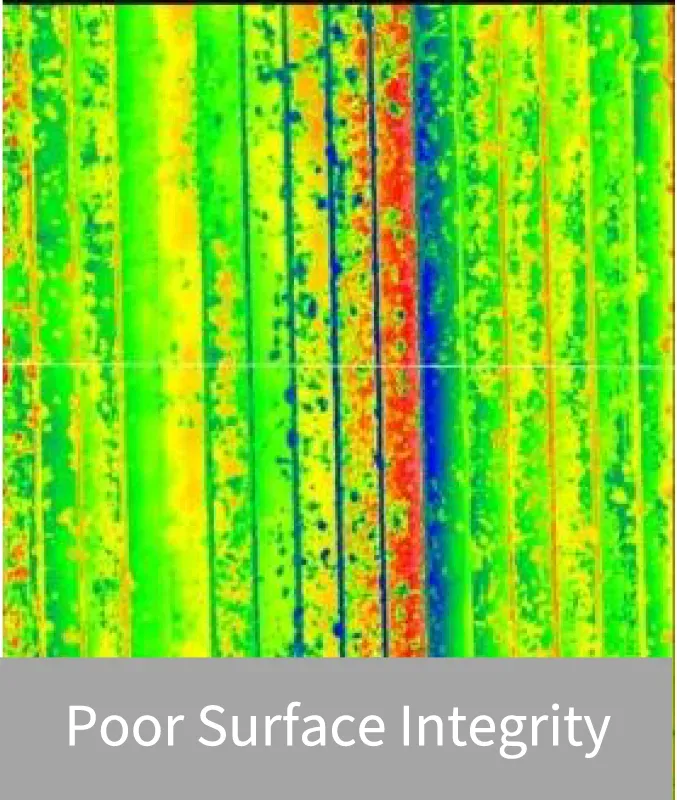

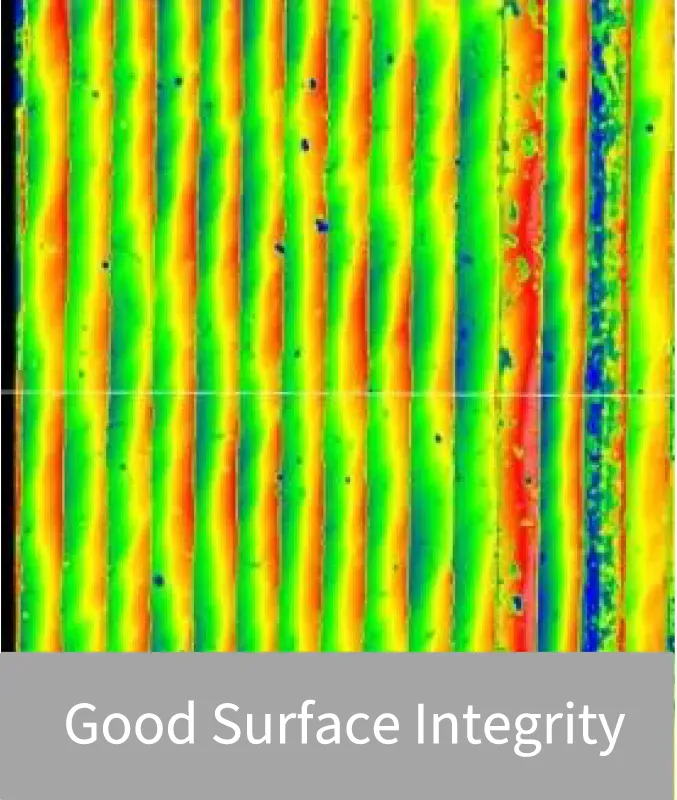

Appearance Comparison

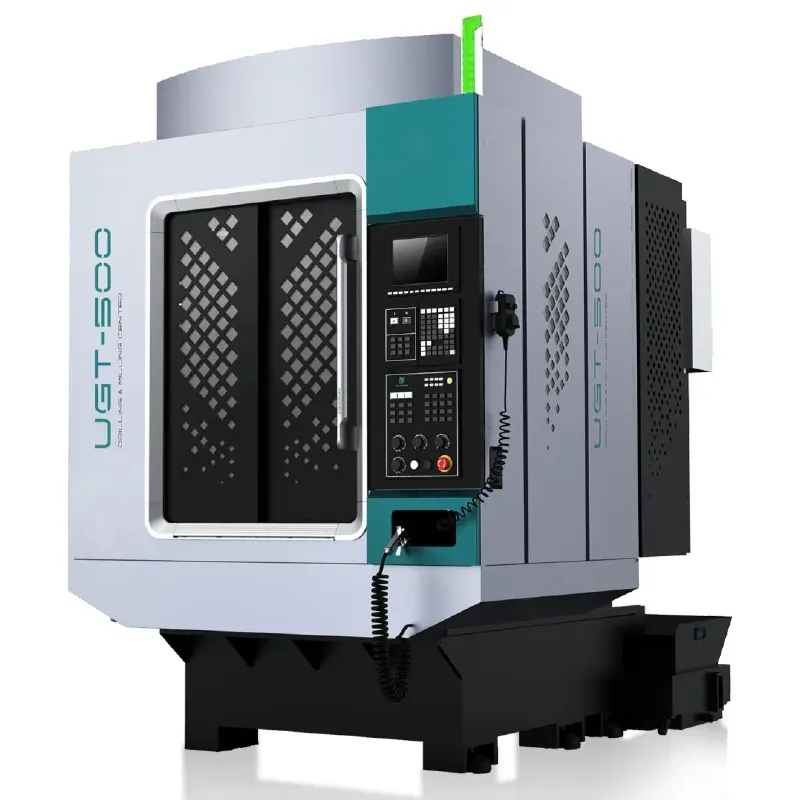

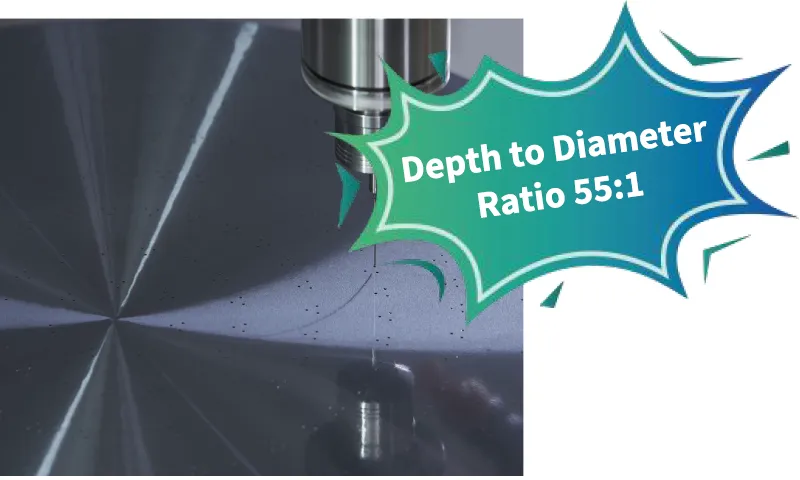

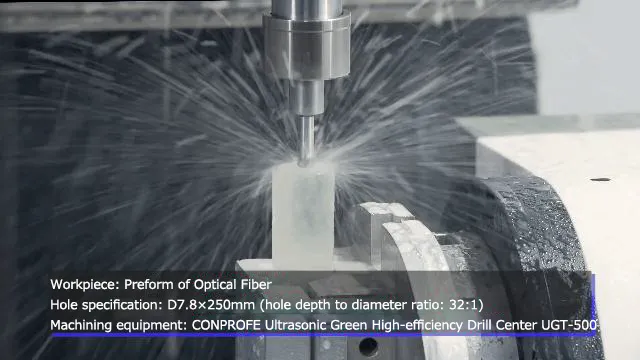

Ultrasonic Drill & Milling Machining Center

Processed Products

Processing of two D7.8x250mm through-holes

Complete Solutions

- Ultrasonic Machining System

- Center Outlet Spindle

Processing Advantages

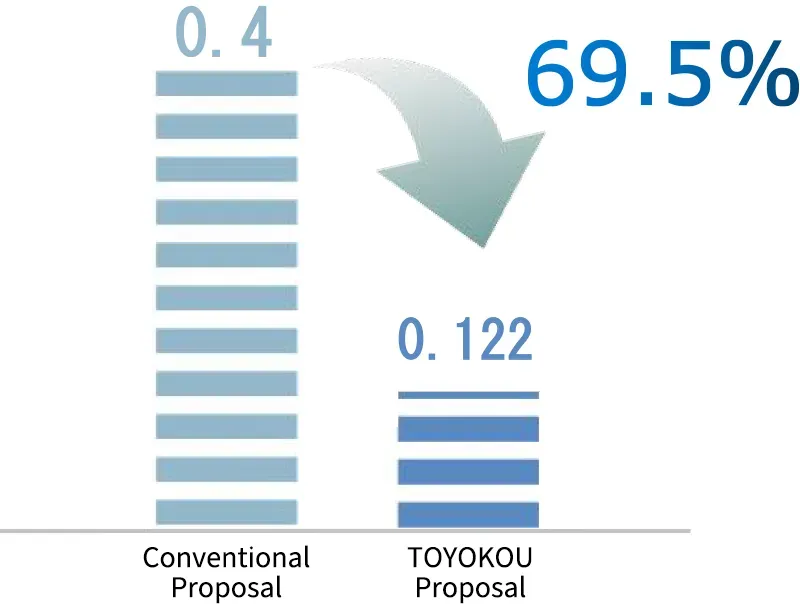

- Hole wall roughness Sa value <0.122μm

- Parallelism of two holes <0.013mn

- Straightness of two holes <0.008mn

Data Comparison

Hole Wall Roughness Sa (μm)

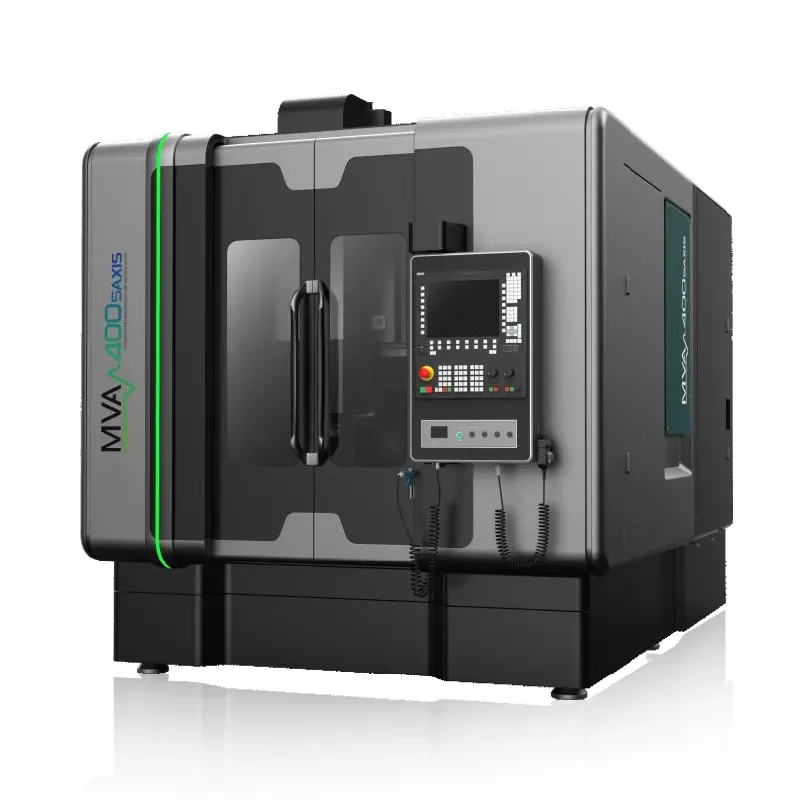

Ultrasonic Green Vertical 5-Axis Machining Center

Processed Products

(Silicon content 70% or more)

D4×45.5mm Drill Hole

Total Solutions

- Ultrasonic Processing System

- Integrated PCD Drill

Processing Advantages

- No burrs or flanging in the hole

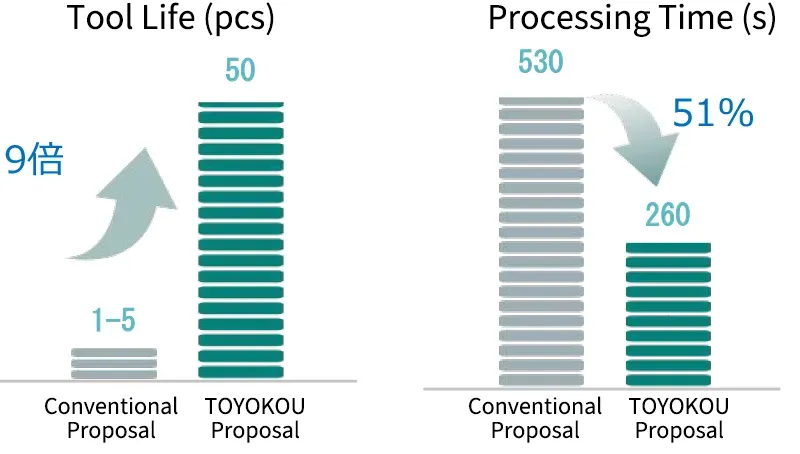

- Tool life extended by 9 times

- Efficiency of single hole processing improved by 51%

Data Comparison

Ultrasonic Precision Graphite Machining Center

Processed Products

Complete Solutions

- Ultrasonic Processing System

- Integrated PCD Fly Cutter

Processing Advantages

- Uniform Surface Pattern

- Significant Reduction in Chipping

- Doubling the Lifespan of Cutting Tools

Application Scene

Graphite | Ceramic Green Bodies | Carbon Fiber Composite Materials

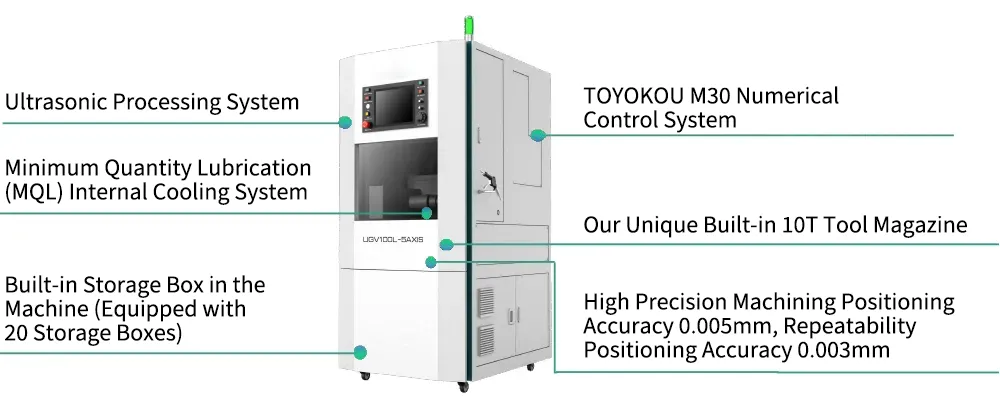

Ultrasonic Green Lightweight 5-Axis Prosthetic Machining Center

Processed Products

Complete Solutions

- Ultrasonic Processing System

- Minimum Quantity Lubrication (MQL)

- Internal Cooling Ring Spray Cutting Tool

Processing Advantages

- No polishing under the gingival margin of the base

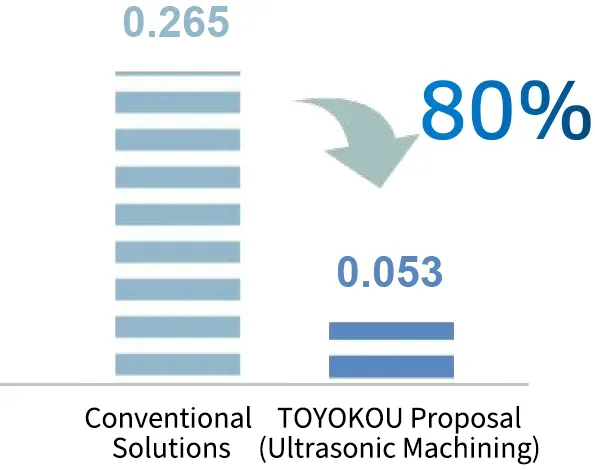

- Surface roughness Sa value <0.053μm

Data Comparison

Roughness Sa (μm)

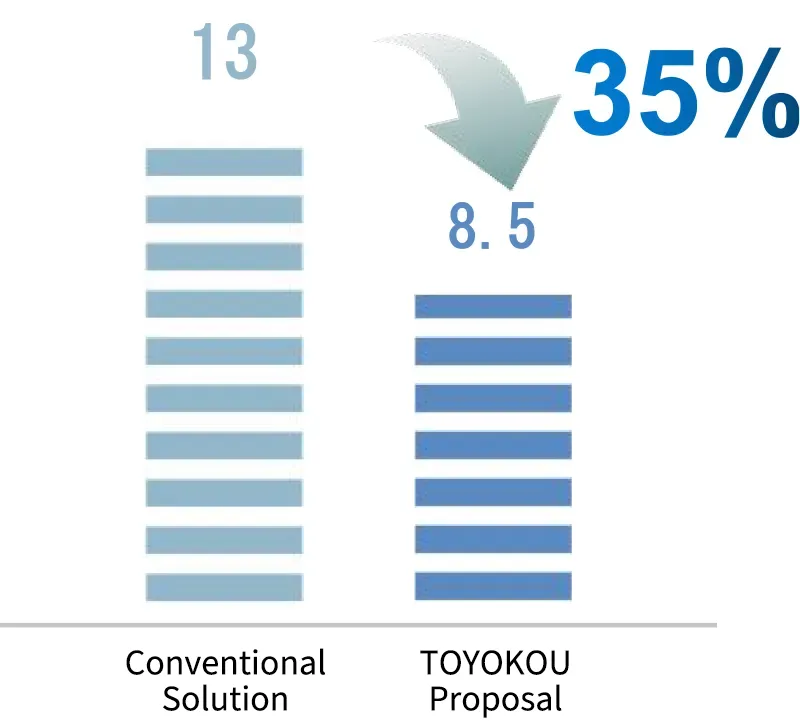

Ultrasonic Graphite Vertical 5-Axis Machining Center

Processed Products

Complete Solutions

- Ultrasonic Machining System

- PCD Micro End Mill

Processing Advantages

- Significant Reduction in Subsurface Damage and Chipping of Ceramics

- Doubling the Lifespan of Cutting Tools

- Reducing Machining Time by 35%

Data Comparison

Machining Time (h)

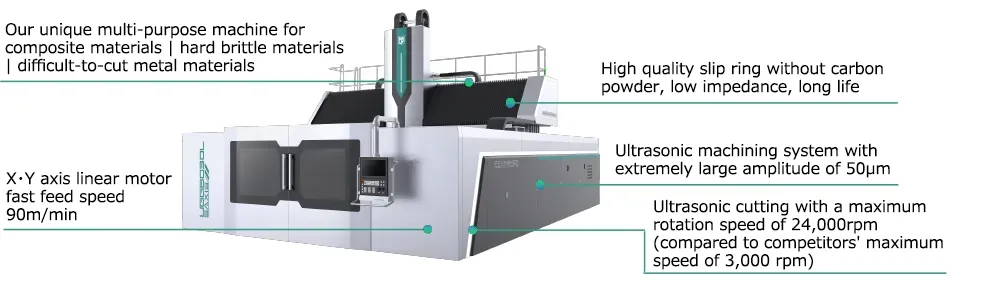

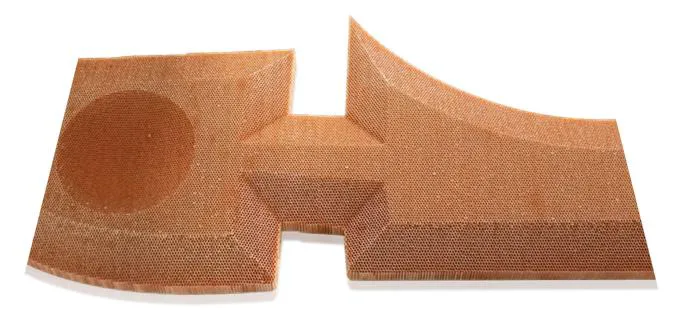

Ultrasonic Gantry 5-Axis Machining Center

Processed Products

Realizes contour machining of small angles (<18°)

Complete Solutions

- Ultrasonic Machining System

- Ultrasonic Cutting Dagger Knife

- Professional Post-processing System

Processing Advantages

- High-efficiency machining of complex 3D contours

- No burrs visible to the naked eye, and no dust

- The surface is flat with no indentations

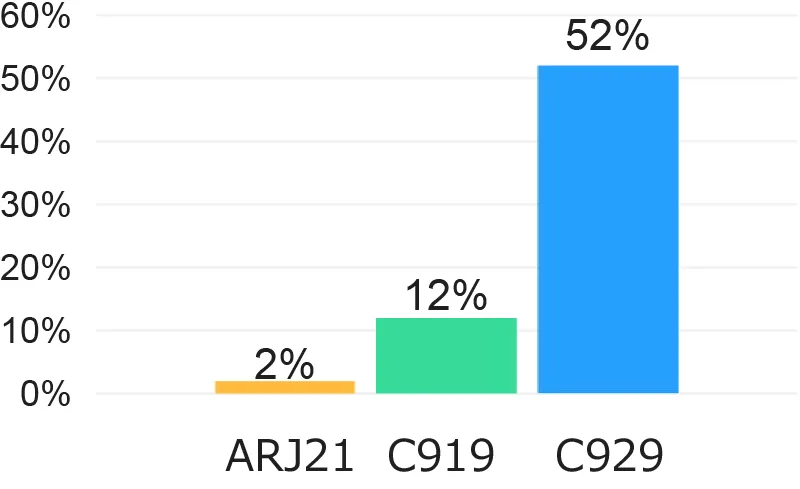

Proportion of Composite Materials

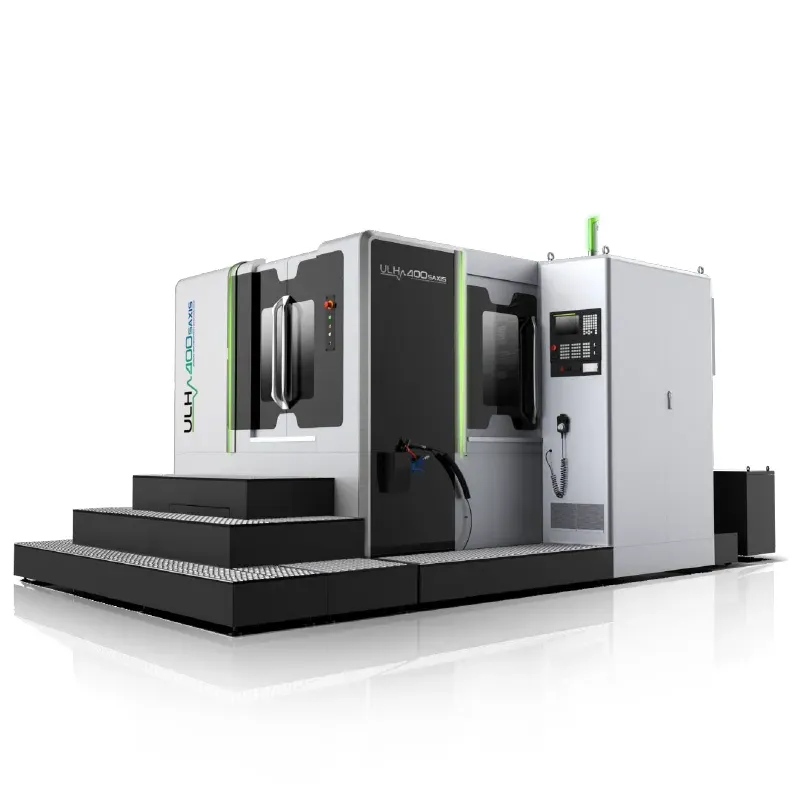

Ultrasonic Green Vertical 5-Axis Linked Machining Center

Processed Products

Complete Solutions

- Ultrasonic Processing System

- Supercritical CO2 Low Temperature Cooling System

- Minimal Quantity Lubrication (MQL) Internal Cooling System

- Ultrasonic Green Heat Shrink Shank

Processing Advantages

- Reduction of blade's thin part chatter

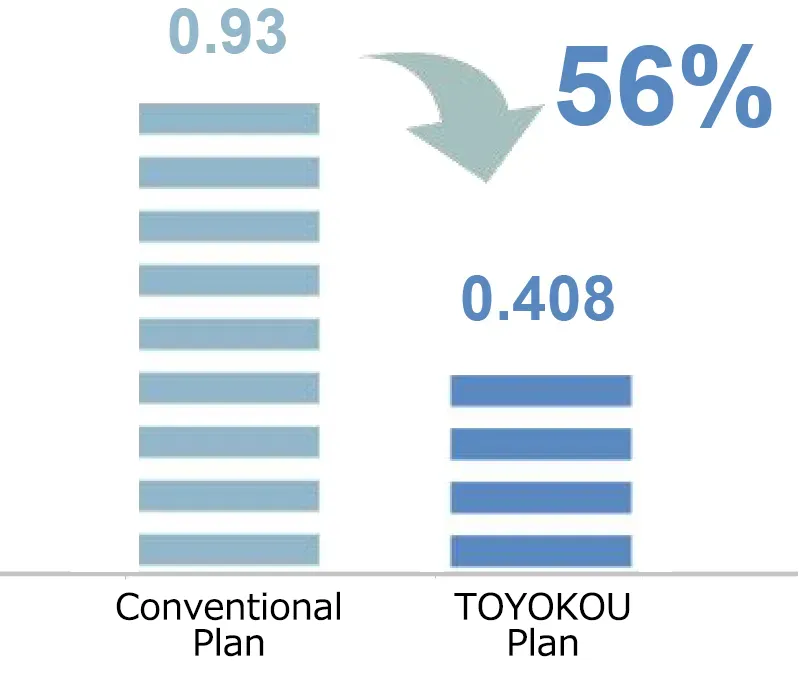

- Reduction of surface roughness Sa value<0.408μm, 56% reduction

Data Comparison

Roughness Sa (μm)