Quartz Substrates for Photomasks

Application:

Substrates such as TGV, DOE, PLC, AWG, etc.

Features:

Extremely low metal impurity content

High refractive index uniformity

Bubble-free

High surface gloss and smoothness

OH content <50 ppm

High refractive index uniformity

Bubble-free

High surface gloss and smoothness

OH content <50 ppm

Optical Properties

| Model | OH (ppm) | Stress Birefringence (nm/cm) | Streak Grade | Transmittance | Internal Transmittance | Recommended Wavelength Range |

|---|---|---|---|---|---|---|

| TSM-6025I | <250 | <10 | 1D | >90.2%@365nm | >99.8%@193/248/365nm | Ultraviolet Region & Visible Region |

| TSM-6025K | <250 | <2 | 1D | >90.2%@248nm | >99.8%@193/248/365nm | KrF |

| TSM-6025A | <50 | <1 | 3D | >90.2%@193nm | >99.8%@193/248/365nm | ArF |

Processing and Inspection Capability

Processing and inspection of quartz substrates for semiconductor mask plates are supported.

- Wire saw processing supported

- CNC precision processing (high-precision cutting supported)

- Double-sided grinding and double-sided polishing supported

- Ultrasonic cleaning and deep cleaning supported

- Defect inspection supported

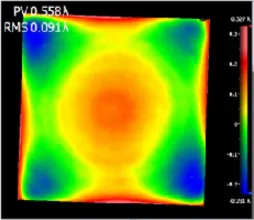

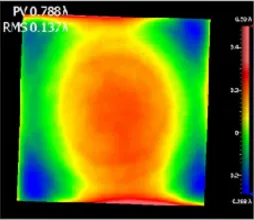

Flatness measurement (using AFM) supported

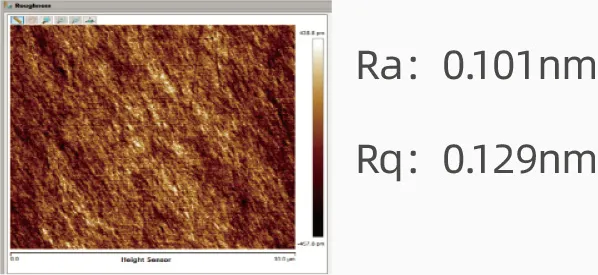

Surface roughness measurement (measurement range: 10 μm × 10 μm)

| Grade | I-line | KrF | ArF |

|---|---|---|---|

| Front (um) | ≤2 | ≤1 | ≤0.5 |

| Back (um) | ≤3 | ≤2 | ≤1 |

| TTV (um) | ≤2 | ≤2 | ≤1 |

| Rms (nm) Front/Back |

≤0.2 | ≤0.2 | ≤0.15 |