Dummy Wafer

What is a dummy wafer?

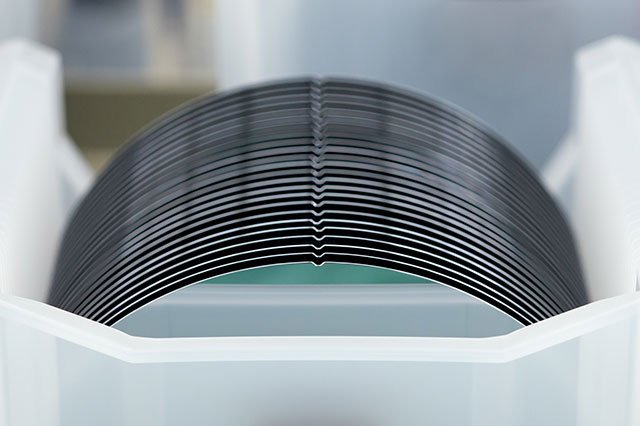

A dummy wafer, also known as a test wafer, is a wafer used primarily for equipment experiments and inspections, unlike product wafers. It is widely used for operational tests of manufacturing equipment, transportation tests, and mechanical evaluations (such as cutting, grinding, polishing, etc.).

Features of Dummy Wafer

Dummy wafers are often used for experiments and tests, so their sizes and thicknesses vary. Sometimes, recycled wafers are also used.

Another characteristic of dummy wafers is that they are less expensive compared to silicon wafer products that are particle-managed. They can also accommodate small-lot shipments.

In manufacturing equipment, the first few dummy wafers are often used to stabilize the process. They are also used to optimize and monitor the manufacturing process. Although dummy wafers are not suitable for device manufacturing, they are quite suitable for monitoring and testing, and are often used as substitutes for new wafers.

Dummy wafers play a crucial role in testing and adjustments at all stages of wafer manufacturing.

Strengths of TOYOKOU CHEMI

- A wide range of products handled

- We have a wide variety of silicon wafers in stock.

- Capable of handling small lots

- We will carefully and meticulously respond to customer requests.

- Short delivery time

- Thanks to our abundant stock, we are able to achieve short delivery times.

- Flexible response

- We can process from ingots for standards that cannot be covered by stock wafers.

At our company, we conduct careful hearings and propose the best wafer to meet the customer's needs.

We can ship in forms that meet your needs, such as in cassette cases or coin roll cases. We also sell wafers without specifying the type or thickness, which can further reduce costs. Please translate all the following Japanese text I send into English according to this standard unless otherwise specified.

| Items | Standards | ||||||

|---|---|---|---|---|---|---|---|

| Size (inches) | 2 | 3 | 4 | 5 | 6 | 8 | 12 |

| Manufacturing Method | CZ / FZ | ||||||

| Type | P-type / N-type / No Preference | ||||||

| Crystal Orientation | <100> / <111> / <110> / No Preference | ||||||

| Notch/Flat Orientation | <100> / <111> / <211> / No Preference | ||||||

| Thickness (μm) | 280 | 380 | 525 | 625 | 625/675 | 725 | 775 |

| Thickness Tolerance (μm) | 20 | 20 | 25 | 25 | 25 | 25 | 25 |

| Resistivity (Ω·cm) | 0.005~ / No Preference | ||||||

| Orientation Flat or Notch | Orientation Flat | Orientation Flat | Orientation Flat | Orientation Flat | Notch or Orientation Flat | Notch or Orientation Flat | Notch |

| Surface Finish | Single Side Mirror (MP/ET) / Double Side Etched (ET/ET) | Double Side Mirror (MP/MP) | |||||

| Particle | Not Specified | ||||||

| Quantity | We accept orders starting from just one piece. | ||||||

| Packaging Method | Coin Roll / Cassette Case | ||||||

| Remarks | The 6-inch OriFla standard is compatible with both JEITA and SEMI. | ||||||