Lithium-ion Battery Separator

A lithium-ion battery separator is one of the important internal parts of a lithium battery structure. Its main function is to separate the positive and negative electrodes of the battery to prevent the two electrodes from touching or short-circuiting. It also enables the passage of electrolyte ions. Its performance determines the interfacial structure and internal resistance of the battery, which directly affect the battery's capacity, cycle, and safety performance. Toyohashi Chemical can adjust the characteristics of the diaphragm and realize customized production according to the development needs of battery customers.

Performance Characteristics

- Excellent Cleanliness

- Excellent Uniformity

- Chemically Stable Characteristics

- Excellent Mechanical Properties

- Good Thermal Stability

- High Safety Performance

- Excellent Porosity

- Excellent Tensile Strength and Puncture Resistance

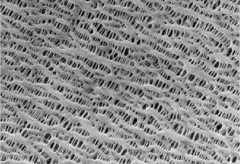

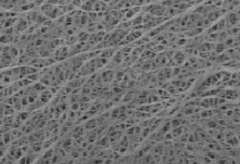

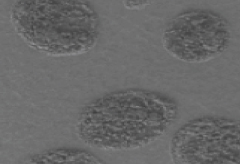

Dry Separator

| Classification | Features | Microstructure | |

|---|---|---|---|

| Dry Separator | High performance, tear-resistant 10-25μm ⸺ Multi-component technology |

|

|

| Inspection Items | Unit | Standard Value | ||||||

|---|---|---|---|---|---|---|---|---|

| Model | KSG10 | KSG12 | KSS14 | KSG16 | KSG20 | KSG25 | ||

| Physical Properties | Thickness | μm | 10 | 12 | 14 | 16 | 20 | 25 |

| Breathability | s/100ml | 180 | 200 | 250 | 280 | 260 | 350 | |

| Puncture Strength | gf | 250 | 300 | 350 | 400 | 420 | 450 | |

| Area Density | g/m² | 5.6 | 6.7 | 7.8 | 8.7 | 11.3 | 13.5 | |

| Porosity | % | 38 | 38 | 38 | 40 | 38 | 40 | |

| 105℃/1h Thermal Shrinkage MD | % | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| 105℃/1h Thermal Shrinkage TD | % | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | |

| MD Tensile Strength | kgf/cm² | 1800 | 1800 | 2000 | 1800 | 1600 | 1800 | |

| TD Tensile Strength | kgf/cm² | 160 | 160 | 160 | 160 | 160 | 160 | |

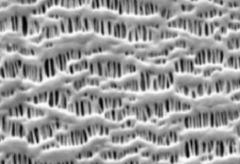

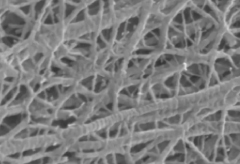

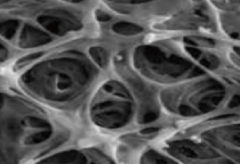

Wet Separator

| Classification | Features | Microstructure | |

|---|---|---|---|

| Wet Separator | Fin-shaped modification, high strength 4~12μm ⸺ Low melting point material |

|

|

| A 7-meter wide separator production line, for higher production efficiency | |||

| Inspection Items | Unit | Standard Value | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Model | KWS05 High strength |

KWS07 High strength |

KWG09 General |

KWH09 High porosity and low air permeability |

KWG12 General |

KWG14 General |

KWG16 General |

KWG20 General |

||

| Physical Properties | Thickness | μm | 5 | 7 | 9 | 9 | 12 | 14 | 16 | 20 |

| Breathability | s/100ml | 140 | 140 | 160 | 60 | 180 | 160 | 170 | 180 | |

| Porosity | % | 35 | 37 | 39 | 50 | 40 | 42 | 43 | 44 | |

| MD Tensile Strength | kgf/cm² | 3200 | 2800 | 2800 | 2000 | 2800 | 2500 | 2500 | 2200 | |

| TD Tensile Strength | kgf/cm² | 3100 | 2800 | 2800 | 1700 | 2500 | 2200 | 2200 | 1900 | |

| Area density | g/m² | 3.1 | 4.2 | 5.2 | 4.3 | 6.8 | 7.7 | 8.7 | 10.6 | |

| MD Break Elongation Rate | % | 85 | 95 | 105 | 98 | 110 | 115 | 115 | 120 | |

| 105℃/1h Heat Shrinkage MD | % | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | |

| 105℃/1h Heat Shrinkage TD | % | 1 | 1 | 1 | 0.5 | 1 | 1 | 1 | 1 | |

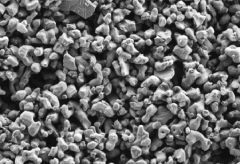

Ceramic Coating Film

| Classification | Features | Microstructure | |

|---|---|---|---|

| Ceramic Coating | High Heat Resistant CCS Coating 150℃→180℃ Coating Thickness 2~3μm |

|

|

| Low Humidity CCS Coating 800ppm→<500ppm Coating Thickness 2~3μm |

|||

| Product Category | Performance | Aluminum Oxide Coating | Bemite Coating | ||||

|---|---|---|---|---|---|---|---|

| General | Low Thermal Contraction | Resistance to Humidity and Heat | General | Low Thermal Contraction | Resistance to Humidity and Heat | ||

| Single-Sided 2u Coating △Breathability: ~20 seconds |

Humidity Moisture/ppm | 400-600 | 900-1300 | 600-800 | 300-500 | 800-1100 | 400-700 |

| Heat Shrinkage <3% at 130℃/1 hour | Y | Y | Y | Y | Y | Y | |

| Heat Shrinkage <5% at 150℃/1 hour | - | Y | - | - | Y | - | |

| Single-Sided 3u Coating △Breathability: ~30 seconds |

Humidity Moisture/ppm | 500-800 | 1200-1600 | 900-1100 | 350-550 | 1000-1400 | 500-800 |

| Heat Shrinkage <3% at 130℃/1 hour | Y | Y | Y | Y | Y | Y | |

| Heat Shrinkage <5% at 150℃/1 hour | - | Y | Y | - | Y | Y | |

| Double-Sided 2-3u Coating △Breathability: ~40 seconds |

Humidity Moisture/ppm | 600-900 | 1600-2200 | 1000-1400 | 400-600 | 1100-1600 | 600-1000 |

| Heat Shrinkage <3% at 130℃/1 hour | Y | Y | Y | Y | Y | Y | |

| Heat Shrinkage <5% at 150℃/1 hour | - | Y | Y | - | Y | Y | |

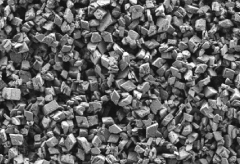

Polymer Coated Film

| Classification | Features | Microstructure | |

|---|---|---|---|

| Polymer Coating | Water-based PVDF Low Cost |

|

|

| Oil-based PVDF High Adhesiveness Width Speed Upgrade Cost Optimization |

|||

| Performance | Unit | Water-based PVDF Spray | Oil-based PVDF | ||||

|---|---|---|---|---|---|---|---|

| 3+2+7+2+3 2-Ceramic 3-PVDF |

5+9+3+5 3-Ceramic 5-PVDF |

9+3+3 3-Ceramic 3-PVDF |

2+5+2 2-Mix Coating |

2+7+2 2-Mix Coating |

1+7+2+1 2-Ceramic 1-PVDF |

||

| Model | KWG07C22P33 | KWG09C03P55 | KWG09C03P03 | KWG05M22 | KWG07M22 | KWG07C02U11 | |

| Thickness | μm | 175(10 layers) | 220(10 layers) | 150 (10 layers) | 8 | 10 | 11 |

| Breathability | s/100ml | 220 | 200 | 200 | 140 | 160 | 170 |

| Total density | g/m² | 10.5 | 12 | 11 | 5.7 | 7.1 | 9.5 |

| The density of the adhesive layer | g/m² | 1.2 | 1.6 | 0.6 | 2.6 | 2.6 | 1.4 |

The main uses of lithium-ion battery separators.

In the structure of lithium-ion batteries, the separator is one of the internal components, playing a very crucial role. Lithium-ion batteries can be used in various fields such as electric vehicles, communications, energy storage, data centers, aerospace, electric boats, mobile power sources, smart homes, and electric tools.